Raw Material Control

We implement a strict supplier whitelist system to ensure that every material entering our production line meets our quality standards. All incoming raw materials, including copper conductors and electronic components, undergo 100% inspection upon arrival. For example, copper used in laminated busbars must pass conductivity testing, while capacitors used in voltage stabilizers are subject to high-temperature aging and screening. By controlling quality at the source, we safeguard the reliability and stability of every product we manufacture.

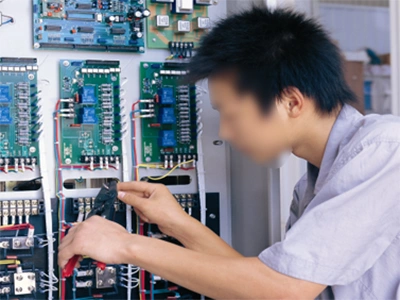

Standardized Production Process

- We follow SOPs (Standard Operating Procedures) across every production stage to ensure consistency and precision.

- For laminated busbar manufacturing, each process: punching, bending, and plating undergoes 100% inspection to guarantee accuracy and uniform quality.

- In reactive power compensation module assembly, we apply automated SMT (surface-mount technology) to minimize human error and enhance reliability.

- During voltage stabilizer testing, we perform three-temperature verification at normal, high, and low temperatures, to simulate extreme operating conditions and confirm stable performance under any environment.

- Through standardized procedures, we maintain process discipline and ensure every product meets our stringent quality benchmarks.

Quality Awareness and Team Engagement

Regular training programs are held to strengthen every employee’s understanding of quality standards and to cultivate a “zero-defect” mindset across all departments. Through a quality points incentive system, team members are encouraged to proactively identify and resolve issues, shifting our quality control approach from passive inspection to active prevention.

In-Process Monitoring and Sampling Inspection

We combine real-time online monitoring with random sampling inspection to ensure product consistency and reliability throughout production. Each production line is equipped with advanced monitoring systems. For example, laser distance sensors in laminated busbar processing provide instant feedback on dimensional deviations. Finished products are tested in accordance with GB/T standards to verify overall performance and safety. Our voltage stabilizers undergo 72-hour continuous full-load operation tests, while reactive power compensation modules are subjected to EMC (Electromagnetic Compatibility) testing to confirm their anti-interference capability.

Preventive Improvement

We take a proactive approach to quality management by using data-driven analysis to identify potential issues before they occur. By tracking and analyzing failure rate data from voltage stabilizers, we can detect when certain electronic components are nearing their service limits. Working closely with suppliers, we then co-develop higher-durability alternatives, improving long-term reliability and product lifespan.

This predictive approach allows us to continuously optimize our designs and maintain stable performance for every product in the field.