Voltage stabilizers, SVG and laminated busbars ensuring stable welding quality and efficient power distribution in automotive assembly lines

Welding is one of the most critical processes in automotive production. During welding operations, unstable voltage can lead to excessive spatter, weak joints, uneven weld seams, and even equipment shutdowns, directly affecting welding precision and production continuity.

Our voltage stabilizers ensure consistent power supply during welding, resulting in uniform weld seams, reduced spatter, and improved joint strength and appearance. They protect robotic welding systems from voltage fluctuations, extend equipment lifespan, and increase overall production efficiency.

View MoreRolling mills and welding machines in automotive workshops operate with short duty cycles and frequent reactive power fluctuations. Traditional capacitor-based compensation devices often fail to respond quickly, leading to low power factor, system instability, and frequent breakdowns, creating safety and efficiency concerns on the production floor.

Our low-voltage SVG systems accurately track real-time reactive power demand under high-frequency, unbalanced loads, providing rapid and precise compensation. This ensures an optimal power factor, stabilizes the grid, and significantly enhances energy efficiency and operational safety within automotive assembly lines.

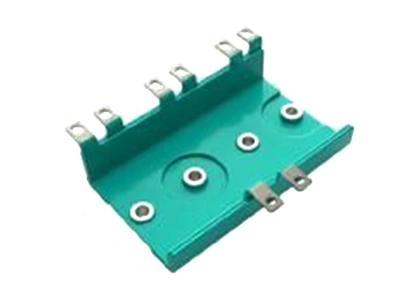

View MoreIn the electric vehicle and bus manufacturing sectors, power distribution systems require components capable of handling high current density, high temperature, and extreme environmental conditions.

Our laminated busbars deliver high transmission capacity and exceptional thermal resistance, operating reliably from –50°C to +125°C (compared to 105°C for conventional products). They withstand humidity levels up to 95% RH at 85°C, ensuring stable performance and safety across diverse automotive power systems.

View More