Static var generator and active harmonic filter enhancing power factor and reducing harmonics for arc furnaces and rolling mills

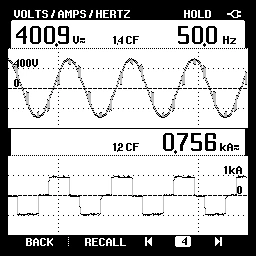

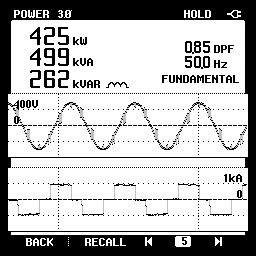

A metal smelting enterprise faced persistent issues in its reactive power compensation system. The workshop’s transformer supplied multiple electric arc furnaces and traditional capacitor banks, but after a period of operation, capacitor units and switching devices frequently burned out or failed to engage. The system’s power factor remained below 0.9, and even after replacing the capacitor banks, failures continued to recur, severely affecting production reliability.

Model: WT-SVG-4L-0.4-200kVar

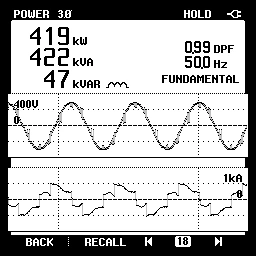

Our low-voltage SVG system replaced the traditional capacitor-based solution, providing dynamic, real-time reactive power compensation. After one year of operation, no capacitor burnout occurred, harmonic levels dropped significantly, and the average power factor improved from 0.85 to above 0.95. The system achieved higher stability, safety, and productivity across the smelting process.

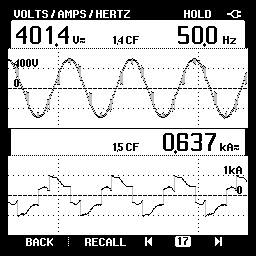

A copper rolling production line in a metallurgical plant used large-capacity variable-frequency drives, which caused severe harmonic voltage and current distortion, resulting in electronic control interference, transformer overheating, and busbar temperature rise.

We implemented two 200A APF units at the low-voltage side of a 1250 kVA transformer for centralized harmonic control. The system achieved THDu < 5%, THDi < 5%, and power factor > 0.95. Electrical interference was completely eliminated, VFD module failures were reduced by 90%, and both transformer and busbar overheating were significantly alleviated, ensuring stable and efficient operation of the entire production line.

View More