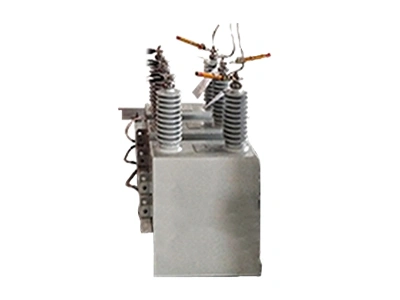

Harmonic Capacitor Banks and Harmonic Filters

Passive harmonic filter for reducing voltage distortion and improving power factor in electrical grids

- Rated capacity: 100–20000kVar

- Rated voltage: 6–35kV

- Wiring method: delta / single-star / double-star

- Ambient temperature: -35℃ to + 55℃ (24h average temperature ≤35°C)

- Atmospheric pressure: 80–110kPa

- Installation location: indoor or outdoor installation

Harmonic capacitor banks and filters are passive devices used in 6 kV, 10 kV, and 35 kV power networks to control harmonics and improve overall power quality. They create a low-impedance path for harmonic currents, reducing voltage distortion and balancing harmonic flow within the system. At the same time, they provide capacitive reactive power to stabilize voltage, enhance power factor, and lower transmission losses.

Harmonic capacitor banks and filters provide efficient harmonic control, voltage stabilization, and reactive power compensation for medium- and high-voltage networks. Their design combines multiple filtering, compensation, and protection functions to enhance system reliability and ensure safe operation under varying grid conditions. The main performance features include the following:

- Continuously detect harmonic currents in the grid and eliminate specific frequency ranges, especially those generated by variable frequency drives and rectifiers, ensuring cleaner and more stable power supply.

- Use high-pass filtering circuits to absorb a broad range of high-order harmonics, which significantly reduces voltage distortion and improves overall waveform quality.

- Offer customized filtering solutions for complex loads such as induction furnaces that produce integer or interharmonics, effectively minimizing severe electrical interference in industrial environments.

- Dynamically compensate reactive power to balance reactive distribution, improve power factor, and reduce line and transmission losses, resulting in higher energy efficiency.

- Maintain voltage stability through the combined effect of harmonic filtering and reactive power regulation, reducing flicker and improving the operating reliability of connected equipment.

- Incorporate a microprocessor-based protection unit that monitors real-time system parameters, automatically protects against overload, and responds quickly to changing conditions.

- Support both manual and automatic control modes, allowing simple operation with precise and flexible switching control.

- Feature a compact structure that minimizes footprint and supports cabinet-mounted or open-rack installation. Open-rack configurations can be equipped with protective fencing, suitable for areas with limited space.

- Adopt a grouped filtering design where single-tuned and high-pass circuits provide low-impedance paths for key harmonics such as the 5th, 7th, and 11th orders. Adjustable reactor inductance accommodates grid impedance variations, preventing resonance and harmonic amplification.

- Utilize high-performance capacitors made of all-film or film-paper composite dielectric materials with a loss tangent ≤0.1 W/kvar and harmonic current tolerance up to 1.8 times the rated value. Intelligent control logic based on dual parameters (reactive power and harmonic) or nine-zone diagrams allows switching response times ≤300 ms to maintain stable power factor.

- Ensure protection through a multi-layer safety system that includes dedicated fuses for individual capacitor isolation, discharge coils for residual voltage suppression, and surge arresters for limiting overvoltage. The integrated microprocessor protection device also provides fast-breaking, overcurrent, and voltage unbalance protection with high precision and reliability.

| Product type | Harmonic Capacitor Banks and Harmonic Filters |

| Model | WT-TAL-#### |

| Rated capacity | 100–20000kVar |

| Rated voltage | 6–35kV |

| Wiring method | 1. Delta 2. Single-star 3. Double-star |

| Ambient temperature | -35℃ to +55℃ (24h average temperature ≤35°C) |

| Relative humidity | ≤90% |

| Atmospheric pressure | 80–110kPa |

| Altitude | ≤ 2000m |

| Wind speed | ≤ 35m/s |

| Installation location | Indoor or outdoor installation |

| Environmental requirements | The installation site shall be free from explosive or flammable materials. The surrounding environment shall not contain substances that corrode metals, or gases and conductive media that may affect insulation performance. Proper protective measures should be taken against rain, snow, wind, and sand. |

Filter Capacitors

Filter Capacitors

Designed with multi-layer oil-immersed or metallized film structures to withstand harmonic currents in power networks

Circuit Breakers

Circuit Breakers

Provide rapid isolation of faulty components, such as individual capacitors, ensuring safe and reliable operation

Series Reactors

Series Reactors

Equipped with adjustable inductance to match system impedance and prevent harmonic amplification

Zinc Oxide Surge Arresters

Zinc Oxide Surge Arresters

Protect the system from operational overvoltage and transient surges

-

Power Systems

Power Systems -

Electrified Railways

Electrified Railways -

Metallurgy Industry

Metallurgy Industry -

Coal Industry

Coal Industry -

Wind Power Generation

Wind Power Generation