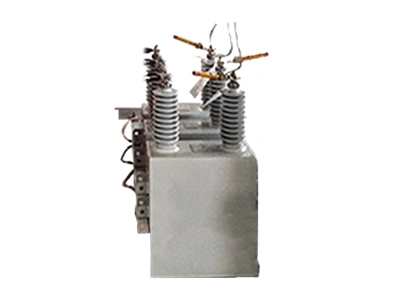

Reactive Power Compensation System

Integrated high voltage capacitance compensation system for reliable power factor correction and grid voltage stability

- Rated capacity: 100–20000kVar

- Rated voltage: 6–35kV

- Wiring method: delta / single-star / double-star

- Ambient temperature: -35℃ to + 55℃ (24h average temperature ≤35°C)

- Atmospheric pressure: 80–110kPa

- Installation location: indoor or outdoor installation

Reactive power compensation systems are essential components in high-voltage power networks. By connecting capacitor banks in parallel to the grid, they provide capacitive reactive power that improves voltage stability and overall energy efficiency. These high voltage capacitance compensation systems help maintain a balanced power factor, reduce losses during power transmission, and support the reliable operation of industrial and utility networks.

- Reactive Power Compensation Systems reduce overall equipment investment by releasing transformer capacity and minimizing the need for distribution network expansion. They also prevent penalties associated with low power factor operation.

- Lower operating costs by reducing reactive current, which decreases transformers and line losses. The improvement is especially noticeable in energy-intensive industries such as metallurgy and rail transport.

- Enhance voltage stability through rapid response to load variations. Reactive power output remains stable even when bus voltage drops, preventing voltage fluctuations or collapse.

- Prevent harmonic amplification that often occurs in traditional capacitor-based compensation systems. This minimizes overheating, mechanical stress, and extends equipment lifespan.

- Centralized compensation configuration helps reduce reactive load on main transformers and high-voltage lines, providing simpler management for most industrial environments.

- Grouped compensation configuration reduces reactive losses in distribution lines and increases transformer utilization efficiency.

- Suitable for various voltage levels, including 6 kV, 10 kV, and 35 kV medium- and high-voltage networks.

- Modular structure is available in indoor cabinet-type and outdoor frame-type designs. Compact layout saves space, allows easy maintenance, and supports detachable inspection.

- Includes comprehensive protection functions such as undervoltage, overvoltage, overcurrent, time-delay tripping, open-delta, differential pressure, and unbalanced current protection.

- TBB-type reactive power compensation systems not only correct power factor but also improve line voltage, reduce voltage drops, and enhance overall power supply stability.

- Provide reliable and cost-effective operations for environments with relatively stable reactive demand. These systems perform effectively under harsh conditions from -35°C to +55°C, suitable for use in cold regions.

| Product type | Reactive Power Compensation System |

| Model | WT-TBB-#### |

| Rated capacity | 100–20000kVar |

| Rated voltage | 6–35kV |

| Wiring method | 1. Delta 2. Single-star 3. Double-star |

| Ambient temperature | -35℃ to +55℃ (24h average temperature ≤35°C) |

| Relative humidity | ≤90% |

| Atmospheric pressure | 80–110kPa |

| Altitude | ≤ 2000m |

| Wind speed | ≤ 35m/s |

| Installation location | Indoor or outdoor installation |

| Environmental requirements | The installation site shall be free from explosive or flammable materials. The surrounding environment shall not contain substances that corrode metals, or gases and conductive media that may affect insulation performance. Proper protective measures should be taken against rain, snow, wind, and sand. |

Capacitor Banks

Capacitor Banks

Act as the main unit of the system, providing capacitive reactive power to offset inductive loads and improve overall power factor

Series Reactors

Series Reactors

Designed to suppress 5th, 7th, and 11th harmonics, preventing resonance between capacitors and system impedance while reducing harmonic distortion

Discharge Coils

Discharge Coils

Reduce residual voltage in the capacitor units after power-off, ensuring safety during maintenance

Zinc Oxide Surge Arresters

Zinc Oxide Surge Arresters

Protect the system from switching overvoltages and lightning surges, preventing insulation damage

Fuse Switches

Fuse Switches

Provide fast isolation of faulty capacitor units to maintain safe and reliable operation

Intelligent Controller (Installed inside the cabinet)

Intelligent Controller (Installed inside the cabinet)

Monitors voltage and power factor in real time, automatically switching capacitor banks on or off to maintain optimal compensation and stable operation

Suitable for power distribution substations of up to 220 kV, including 6 kV, 10 kV, and 35 kV busbars. Commonly used for reactive power compensation and on-load voltage regulation in substations

For high-voltage systems (10kV/35kV) that require stable reactive power compensation, such as new factory substations, which product should be selected?

A high-voltage reactive power compensation system is recommended. It offers a cost-effective solution for stable load conditions, improving the power factor and preventing penalties for low efficiency.

How to choose between different reactive power compensation products for stable loads (e.g., textile factories) and fluctuating loads (e.g., electric arc furnaces)?

For stable loads, high-voltage reactive power compensation systems are suitable. For fluctuating loads, high-voltage SVGs or low-voltage SVGs should be used, depending on the grid connection level.

Can high-voltage reactive power compensation systems operate in environments with temperature variations or harsh conditions?

Yes. These power compensation systems are designed to function reliably in a wide temperature range (−35°C to +55°C), which is suitable to use in high-altitude or cold regions.